3D Printing & 3D Scanning>>>Computer & Office

Brand Name szSHOOMO

Origin CN(Origin)

Item Type Screw Nut

Model Number Brass Heat Set Insert Nut

Size

M3 x OD4.2 x H3.0

M3 x OD4.2 x H3.6

M3 x OD4.2 x H3.8

M3 x OD4.2 x H4.0

M3 x OD4.2 x H4.5

M3 x OD4.2 x H5.0

M3 x OD4.2 x H5.5

M3 x OD4.2 x H5.7

M3 x OD4.2 x H6.0

M3 x OD4.2 x H6.5

M3 x OD4.2 x H7.0

M3 x OD4.6 x H3.0

M3 x OD4.6 x H3.6

M3 x OD4.6 x H3.8

M3 x OD4.6 x H4.0

M3 x OD4.6 x H5.0

M3 x OD4.6 x H6.0

M3 x OD4.6 x H7.0

M3 x OD5.0 x H3.0

M3 x OD5.0 x H4.0

M3 x OD5.0 x H5.0

M3 x OD5.0 x H7.0

Knurled Brass Embedment Nuts M3 Thread Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support Custom 100PcsUSD 3.00-7.40/piece

Knurled Brass Embedment Nuts M3 Thread Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support Custom 100PcsUSD 3.00-7.40/piece Knurled Brass Embedment Nuts M5 M6 Thread Heat Set Insert for Printing 3D Printer Accessories Parts Support Custom 100PcsUSD 3.50-5.20/piece

Knurled Brass Embedment Nuts M5 M6 Thread Heat Set Insert for Printing 3D Printer Accessories Parts Support Custom 100PcsUSD 3.50-5.20/piece Knurled Brass Embedment Nuts M2 Thread Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support Custom 100PcsUSD 5.20-6.40/piece

Knurled Brass Embedment Nuts M2 Thread Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support Custom 100PcsUSD 5.20-6.40/piece 50Pcs M4 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 5.00-6.80/piece

50Pcs M4 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 5.00-6.80/piece 100Pcs M2.5 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 5.60-6.40/piece

100Pcs M2.5 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 5.60-6.40/piece 100Pcs M2 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 5.20-6.70/piece

100Pcs M2 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 5.20-6.70/piece 20Pcs M5 M6 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 3.50-5.00/piece

20Pcs M5 M6 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 3.50-5.00/piece 100Pcs M3 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 3.30-7.50/pieceProduct Introduction:Name:Heat Set Insert NutBrand:SHOOMOMaterials:Brass

100Pcs M3 Thread Knurled Brass Embedment Nuts Heat Set Insert IUB IUC for Printing 3D Printer Accessories Parts Support CustomUSD 3.30-7.50/pieceProduct Introduction:Name:Heat Set Insert NutBrand:SHOOMOMaterials:BrassColor: Golden

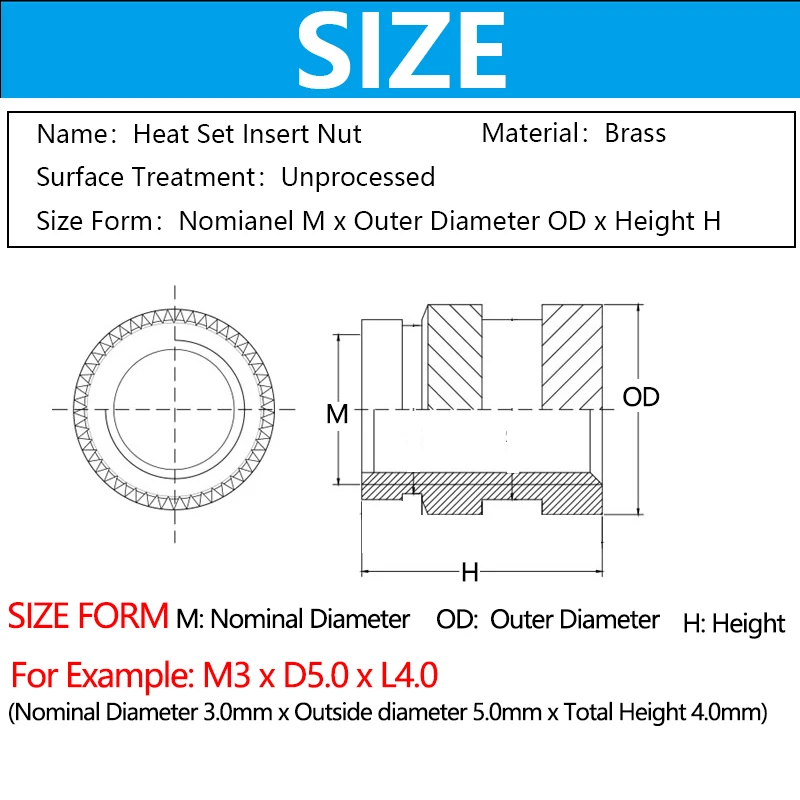

Size Form:Nomianel M x Outer Diameter OD x Height HSize Form:

SIZE FORM: M(Nominal Diameter) x OD(Outer Diameter) x H(Height)

For Example: M3 x D5.0 x L7.0

(Nominal Diameter 3.0mm x Outside diameter 5.0mm x Total Height 7.0mm)

Stock List

Product Advantage:

No need to counterbore or countersink the boss hole because the insert has guide pilot.

Can be installed by ultrasonic or heat in tapered bore wire, or molded in during injection.

Easy to install: From the moment that the insert has a valve conduit, there is no need to back-drill and counter-sink the hole.

All nuts are made of high quality brass, which has high hardness, no deformation, durable and reliable for long use.

Used on injection moulding for tightly fixing.

Usage Scenario:

High-quality Materials, Excellent Technology.

The inserted nut is made of high-quality 59 brass, which has high hardness, oxidation resistance and corrosion resistance.

It is processed by automatic lathe, with accurate size, uniform tooth pitch and no burrs.

Knurled Design, Standard Nut.

The knurled nut design increases the embedded friction and makes the nut more stable.

The thread is deep, the force is even, the thread is accurate, and it is not easy to slip during rotation.

Complete in Size and Complete

A full range of sizes and matching bolts can be purchased according to your needs, a one-stop shopping experience.

How to Use

Tapered threaded brass inserts for 3D Printing.

Easy to set in an appropriately-sized hole in the part using a soldering iron. Numerous vanes and ridges around the insert allow plastic to flow between them, creating a tough bond with the printed part.

Product Photos

No comments:

Post a Comment